◖ND SOLUTIONS

Oil products and related products automated metering system increases the efficiency of business process management, and eliminates the main problems of the industry.

The introduction of automatic control elements increases compliance with quality standards, optimizes the logistics system, improves the discipline of operating staff. This reduces losses and increases the profitability of the business, contributes to the improvement of the company’s image, and in the conditions of severe competition helps to win in the fight for a client.

It is with this goal in mind that ND has developed a concept and created a software and hardware complex to automate the components of the oil and gas business that can solve the tasks of both national companies and transnational oil corporations.

The solution is aimed at quantitative and qualitative improvement of business indicators:

- Increase of profitability, reduce of losses and risks

- Improvement of the efficiency of operational management

- Control of business processes, personnel actions, remote facilities, transportation

- The fight against theft and fraud

- Increase of the level of facilities security

- Formation of positive reputation of the company.

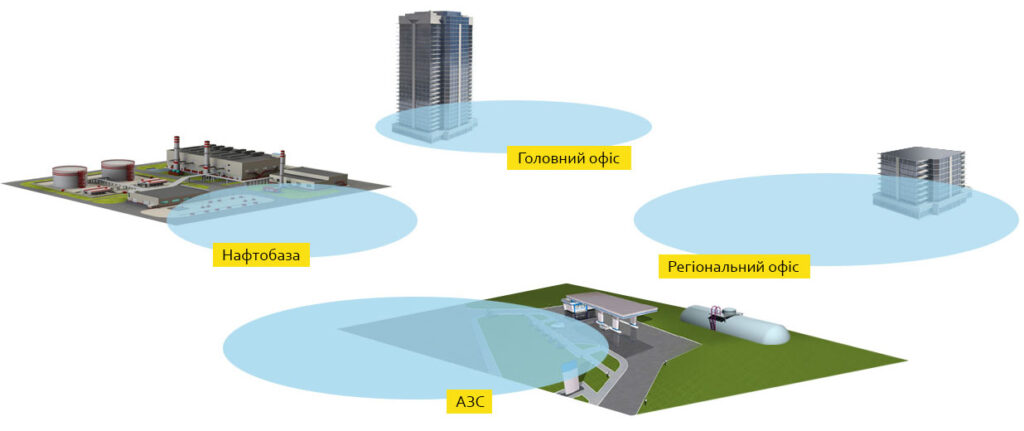

Facilities for automation

The ND solution is designed taking into account the features of automation of all elements of the oil and gas complex. It was based on the modularity principle, which allows you to scale the system as the structure of the complex changes.

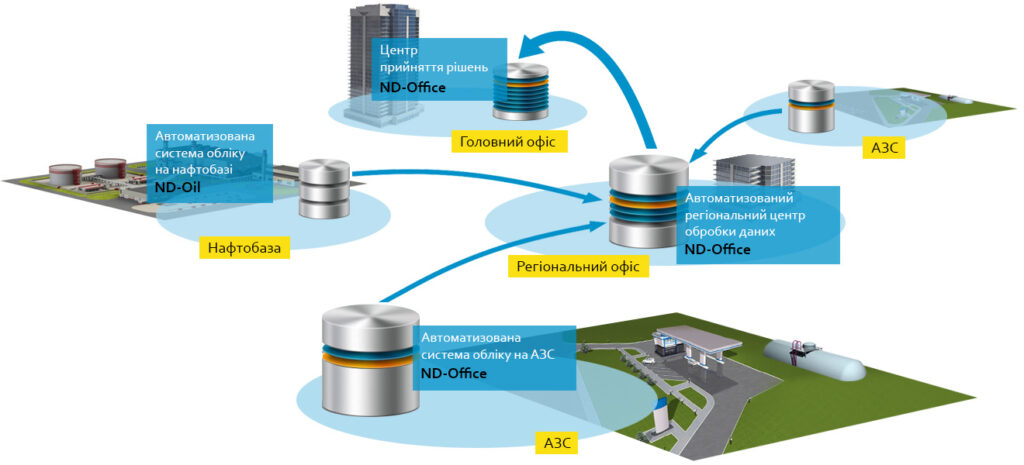

Structure of the solution

Complex automation is designed for the automation of operation processes of the companies that deal with wholesale and retail trade of oil products, gas and related goods.

- In the tank battery of the complex, ND control and measuring equipment is installed, operator automated working station is automated. Every 5 minutes, the control and measuring equipment determines the level and physical parameters of the fuel in the tank and transfers the data to the operator automated working station.

- In parallel with fixing actual fuel measurements in tanks, the system reads data from cash registers on a real-time basis.

- Using modern means of communication, the server part of the system transmits to the regional office the processed data received from the filling stations, every 5 minutes, from the petroleum storage — every 30 minutes and every hour all kinds of data are transmitted to the head office.

ND System software transmits the processing, comparison and output data in automatic mode, in real time and without human input.

The system accumulates 2 data sets, measured at a given periodicity: the quantity and physical parameters of fuel in the tanks, as well as the number of sold and receipted fuel according to the payment system data.

The system is equipped in advance with formula for the calculation of physical parameters of a particular oil product in different temperature regimes. These formulas calculate the “normal” state of the fuel at current temperatures.

Along with the measured and calculated data, the system stores the so-called “fine-adjusted” parameters of the oil complex element itself. They include, for example, daily volumes of fuel flow, schedule of fuel delivery or unload, time of the shift change, allowed idle time intervals, etc.

Further data processing is based on factor analysis. Comparison of the first three data sets, taking into account the individual parameters of the components of the oil and gas complex, allows drawing conclusions about their work. Here are some of them:

- The absence of sale of fuel by fuel types and pistols, a long “staff change”

- Lack of connection with the level gauge

- Atypical change in mean density and / or fuel temperature

- Change of accumulated water level

- Change of actual balances between shifts

- Exceeding of growth rate or deviation of the fact / book difference by fuel type

- The discrepancy between the calculated and actual physical parameters of the fuel: density, volume, mass

Having discovered the problem, the system sends an alarm signal to the decision centers.

The system transmits the received and processed information on the operator screens in a human-readable language.

The current data is displayed on a real-time basis, and, on demand, the stored data for any previous period can be displayed. This happens in the following order.

- Based on the data obtained from the metering equipment, a diagram of actual fuel behavior is drawn.

- Based on the data received from the cash register of the filling station, a diagram of calculated fuel behavior is drawn.

- Along with these two diagrams, the system draws a third diagram based on a mathematical model of the typical behavior of oil products under a given temperature regime.

- Comparable data in the form of diagrams is continuously displayed on the screens of the operators of the filling stations and the regional center. And if a problem is detected, the ND System transmits an alarm signal to the decision centers (to minimize the risks associated with the human factor, the ability to transmit an alarm signal to several decision centers is realized).

It does not end the ability of the system to present current metering data. It is possible to create complex daily reports for the top management of the network:

- Report on the sale of fuel and related products

- Report on payment type

- Report on the fuel remains in the tanks

- Cash flow report

Types of solutions

By the term “typical” we mean complex solutions, the hardware part of which is built on the specialized technology of ND Group partners: IBM, Toshiba, Dallmeier, Epson, Citizen.

A “typical” solution is applicable when it comes to automation of a new component of an oil and gas complex or a complex reorganization of an existing facility.

“Price/quality” rate of this solution is optimal, because at its designing not only technical parameters of the equipment are taken into account, but also their compatibility, expected operating conditions, wear rate, maintenance costs, residual cost and much more.

As for the software, depending on the facilities of automation, either ND-Office or ND-Oil is installed.

By a word “adaptive” we call a complex solution, the hardware part of which is implemented on the basis of already used equipment.

The solution is preceded by an examination, which establishes the principal possibility and the expected efficiency of the automation system on the basis of the used equipment.

Such tasks are claimed by market participants in different degrees, therefore they are called private. However, they are all related to automation processes and / or metering analysis.

The presence of the R&D department allows ND to cope with tasks of any complexity.

Unlike complex automation, in which, first of all, the owner and top management are interested, the representatives of the specialized departments become the initiators of these tasks. It can be:

Maintenance department

IT department

Internal security service

Control and audit department

Staff department

Logistics service

Commercial and financial departments